- News

- Intro and Press

- Details of the project

- Related Publications

- Youtube Video presenting the project

- August 2025: Our new review paper open access is published "Machine learning-driven computational screening of covalent organic frameworks for gas separation applications,” Separation and Purification Journal (2025)" Read the paper here.

- April 2025: we had a vey fruitful meeting with our REDIAL patients ...interesting to hear about all the personal stories and regional policies on Dialysis. Also, very interesting to know about the electricity consumption associated to home dialysis!

- March 2025: we attended the Crick Symposium organised by Kidney research UK in London, where we presented a poster on the REDIAL project

- February 2025: our new paper entitled "Chemical engineering contribution to hemodialysis innovation: achieving the

wearable artificial kidneys with nanomaterialbased dialysate regeneration" has been published OPEN ACCESS on Physical Sciences Reviews, 2025 - December 2024: We published a review paper entitled ‘Sorbent-based dialysate regeneration for the wearable artificial kidney: Advancing material innovation via experimental and computational studies’, Separation and Purification Technology . You can find the link to the open access paper here: https://doi.org/10.1016/j.seppur.2024.130776

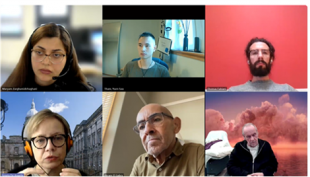

- November 2024: we had our periodic patients update meeting, and we were pleased to welcome a new participant to the study. The participants included Grazia De Angelis (PI of the Redial Project), Thomas Fabiani (PhD Student), Maryam Zarghamidehaghani (Postdoctoral Researcher), Akram El Gabri (Co-chair, Renal (MedTech) and Kidney Patient Under Hemodialysis), Fraser Mclellan (Kidney Patient Undergoing Hemodialysis), Tham, Yuen Sau (Kidney Specialist, NHS Greater Glasgow and Clyde).

- October 2024: We received funding for a PhD studentship from the UKRI Artificial Intelligence Centre for Doctoral Training in Biomedical Innovation at the University of Edinburgh starting in Autumn 2025.

- September 2024: the REDIAL project wins the Best Poster Award at the Driving Discoveries event organised by Kidney Research UK in Nottingham, 4-5 September 2024. Congratulations !

- Our patients list has been updated.

BBC Scotland;

The Herald;

Renal Interventions;

Kidney Research UK

Edinburgh Innovations Magazine

The project entitled "REDIAL-Redefining hemodialysis with data-driven materials innovation: towards miniaturization and the wearable artificial kidney ", ref: KS_RP_012_20221129 has been approved for funding by Kidney Research UK (£180,644.56).

The PI is prof. Grazia De Angelis and the co-Is are dr. Simone Dimartino from the Institute of Bioengineering and prof. Sotirios Tsaftaris from the Institute of Digital Communications.

The program will last 2 years and will study, using AI and molecular simulation techniques, together with experimental analysis optimal materials for the removal of uremic toxins from dialysate streams with the aim of developing wearable dialysis.

The program is highly interdisciplinary ad combines material science, chemical engineering, bioengineering and artificial intelligence.

Hemodialysis (HD) is a therapy replacing kidney functionality, which has a huge impact on the patients’ life and is not equally accessible to all. Nevertheless, the HD technology has remained unchanged for decades as it is considered safe, and innovations have very long time-to-market.

Our methodology, based on data-driven innovation of materials, has the ambition to redefine hemodialysis, achieving the miniaturization of the technology. This advancement will make home dialysis more accessible and the wearable artificial kidney (WAK) possible, with significant improvements to the patients’ life.

Home dialysis can be carried out more frequently than in the hospital, reducing the stress on the body and the need for strict dietary regime. Home treatment also improves the patients’ lifestyle and makes HD more accessible to those living in remote areas, with mobility issues or with poor heart condition.

Unfortunately, current home HD devices use the same technology as hospital machines and require space and renovations that only a few can afford, besides being energy and water intensive.

Making the HD units more compact, and even transportable or wearable will allow more patients to access home treatment and benefit from its advantages, simultaneously reducing the use of resources and the burden on the NHS.

The miniaturization of HD requires the introduction of a water regeneration device after the dialysis, that purifies the toxin-rich water and recirculates it to the blood cleaning section. The majority of compounds present in dialysate water can be abated with conventional filters, while urea is too small a molecule to be completely depleted with standard filtering materials.

The urea removal has been so far the main technological barrier towards the development of a WAK: previous prototypes adopted a chemical reaction, a method creating by-products that can enter the patient’s blood causing health issues.

We believe that the solution can be achieved without chemicals: recent discoveries provide a wide portfolio of new materials with nanopores that can be potentially be finely tuned to permanently capture urea from water, acting as selective nanosponges.

In particular, we envision a multilayer structure where water is first cleaned from non-urea compounds with a conventional filtering material, and then passes through the innovative nanosponge that depletes the residual urea. Such material has to be safe and not release any harmful component.

The experimental selection of the optimal urea-removing material is time-consuming because it requires to perform tests on many potential candidates. To accelerate the material design and discovery process we will make use of Artificial Intelligence, and in particular of a Machine Learning (ML) algorithm.

- "Chemical engineering contribution to hemodialysis innovation: achieving the wearable artificial kidneys with nanomaterial-based dialysate regeneration" Physical Sciences Reviews, 10, 3, 2025, 279-299. https://doi.org/10.1515/psr-2024-0055.

- Sorbent-based dialysate regeneration for the wearable artificial kidney: Advancing material innovation via experimental and computational studies Separation and Purification Technology 2025, 360, 130776. https://doi.org/10.1016/j.seppur.2024.130776

-

In silico screening of nanoporous materials for urea removal in hemodialysis applications Physical Chemistry Chemical Physics, 2023, 25(35), pp. 24069–24080, https://doi.org/10.1039/D3CP01510F

-

Mixed Matrix Membranes Adsorbers (MMMAs) for the Removal of Uremic Toxins from Dialysate, Membranes, 2022, 12(2), 203, https://doi.org/10.3390/membranes12020203